Magnetic Dent Removal System (MDRS)

What is MDRS?

Dent repair is often a costly and time-consuming challenge. The Magnetic Dent Removal System (MDRS) was developed by technicians Eric…

What is MDRS?

Dent repair is often a costly and time-consuming challenge. The Magnetic Dent Removal System (MDRS) was developed by technicians Eric Satterlee and Wayne Tanabe to make this difficult task easier and faster by using Rare Earth magnets to assist with the repair.

When brass is manipulated, it becomes more brittle and susceptible to cracking and further injury. This is due to the stretching of the materials during the repair. The MDRS offers a safer alternative that alleviates much of this distress. It is especially helpful when repairing hard-to-reach dents that normally would require extensive time disassembling and reassembling the instrument.

How it Works

Using the MDRS involves rolling a steel ball inside and along the dented area of an instrument. The MDRS Tools (Flat Tool and Radius Axial Tools) are used on the outside of the instrument to attract the steel ball. Using a back and forth motion, the magnet pulls the steel ball through the body of the instrument and removes the dent safely and quickly.

The MDRS Tools come with a Mylar Disc and Spray Wax to prevent scratching the instrument.

The MDRS Tools contain one of the strongest Rare Earth magnets currently available – the N52 – which is encased in a patented handle assembly with “Armor-Plate” end discs. These end discs are 1-2” thick and are impervious to cracking, chipping, scratching, etc. and possess a superior lubricity characteristic.

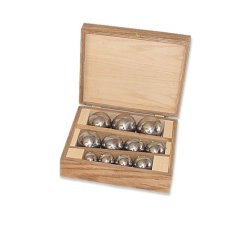

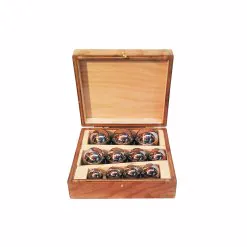

A technician can use a variety of sizes of both solid and hollow steel balls with the MDRS Tools to allow flexibility in repair work. This range of sizes allows the technician the ability to adapt the size ball to fit different hard-to-reach areas of the instrument. The hollow balls are lighter and require less physical effort than the solid versions.