JLS Cork Pad Spinners

Batch Built$27.50

Cork pads often fit a pad cup right to the wall of the cup. This is good for function and aesthetics, but this does create a challenge when trying to float the pad.

Without a loose fit in the cup or an accommodating shape to the pad, there can be no room for tipping the pad while floating. We can help with that.

The JLS Cork Pad Spinners take this challenge on by helping you form the pad with either a bevel, step, or radius on the cup side of the pad so that it will float gracefully in the cup while still filling across the diameter.

If you wish, you can acquire an even larger diameter of pad against the tonehole if you create a stepped back which allows the larger diameter pad to fit in the cup.

The JLS Cork Pad Spinners are also used to shape the tonehole facing side of the pad so that you can get the venting and reduced turbulence as you wish. Beveling or radiusing the face is often used on clarinet register pads as example.

To use:

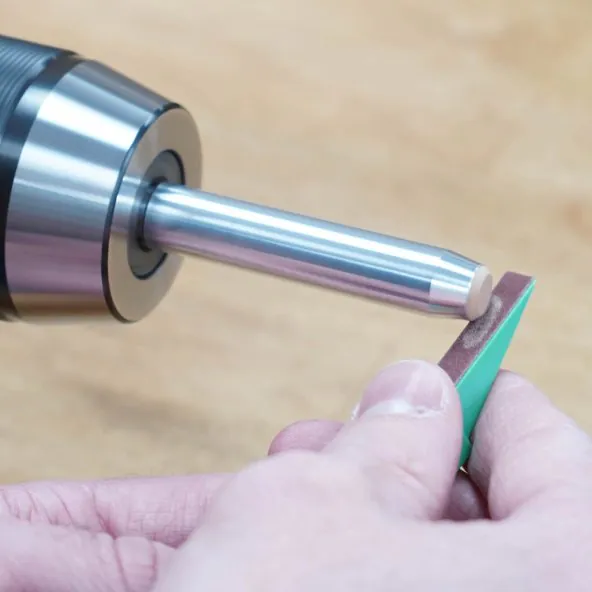

Select the pad and mount the corresponding size Pad Spinner in your bench motor. Gently insert the pad straight into the cup on the end of the Pad Spinner. The Spinner should hold the pad securely.

Under power, you may sand (try 400 grit) or file (try a #4 cut) a bevel or radius on the exposed edge of the pad.

There is a through hole for pushing the pad out (rather than pulling it with fingernails) using a stick of your choosing. It’s good to have a dedicated stick with a blunt tip so it leaves no mark on the pad surface.

JLS Cork Pad Spinners are designed for pads 2.8mm (.110”) thick.

Tip: Given the imprecise nature of many bench motor chucks, we recommend finding the “sweet spot” where the Spinner runs true and marking it for next time. Perhaps make a permanent mark on the bench motor chuck and then mark the Spinner correspondingly after finding the place where it runs truest. This is a great approach for many tools used in the bench motor.

Instructions:

Batch Built is a description we apply to our machined tools that are periodically made in batches.

Each time we make a new batch, the product’s design, function, specifications, and materials are reviewed with the design and production teams. We are constantly improving our tools and finding ways to make them more economically.

Although we work hard to ensure our essential tools, pads, parts and supplies are always available, Batch Built tools are not in stock at all times.

How can I order Batch Built tools?

If a Batch Built tool is out of stock it cannot be ordered, but you can enter your email address on the product page in the field “Email when stock available” and click “Notify Me”.

We don’t want to hold up orders that include Batch Built items if they cannot be delivered, particularly if those items are not yet on our production schedule and have no ETA.

Which items are Batch Built?

Click here to see a full list of Batch Built tools.