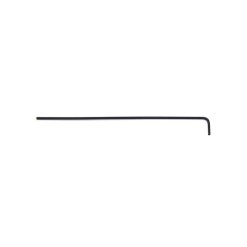

JLS Double Handle Burnisher

Batch Built$59.50

Our Double Handled Burnisher is primarily for flute headjoint fitting. This can be used with our JLS Flute Headjoint Fitting Mandrel.

14 in stock

Our Double Handled Burnisher is primarily for flute headjoint fitting. This can be used with our JLS Flute Headjoint Fitting Mandrel.

With the headjoint mounted on the fitting mandrel, select an area to work, and rotate this to the top and center. With moderate and even downward pressure, push the burnisher towards the vice. After 3 or so moderate strokes, blend the area with surrounding areas by burnishing with a lighter pressure. Then view the tenon from the end to check for roundness. You may also use our plug gauges for this. When final fit is arrived at, dress the tenon with 600 grit paper, then 3200 grit Micro-Mesh™. This may loosen the fit a little bit, so it is best to burnish until it is snug.

Always be sure the surfaces of both the work piece and the burnisher are free from dirt, oil, and dust. Polish the burnisher to remove any defects. I recommend Micro-Mesh™ for this, but you may also polish with Tripoli. Be careful of heat buildup – the plastic handles can be damaged.

View InstructionsBatch Built is a description we apply to our machined tools that are periodically made in batches.

Each time we make a new batch, the product’s design, function, specifications, and materials are reviewed with the design and production teams. We are constantly improving our tools and finding ways to make them more economically.

Although we work hard to ensure our essential tools, pads, parts and supplies are always available, Batch Built tools are not in stock at all times.

How can I order Batch Built tools?

If a Batch Built tool is out of stock it cannot be ordered, but you can enter your email address on the product page in the field “Email when stock available” and click “Notify Me”.

We don’t want to hold up orders that include Batch Built items if they cannot be delivered, particularly if those items are not yet on our production schedule and have no ETA.

Which items are Batch Built?

Click here to see a full list of Batch Built tools.

Related products

SKU: 12705