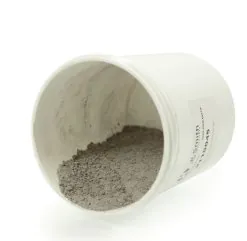

Artifex Peripheral Grinding Wheels

$61.70 – $90.65

These long lasting peripheral precision grinding wheels are unique in their ability to conform to the contours of the workpiece. They are commonly used in the jewelry industry (as well as many other industries) as they work great on precious metals (gold, silver, platinum) as well as non-ferrous metals (aluminum, copper), steel and a variety of other materials.

Specifications:

- Silicone Carbide

- 5.9″ (150mm) OD

- .5″ (12.7mm) ID

- Available in 2 grits (150 Medium Grit and 250 Fine Grit) across 3 thicknesses

- Use in a bench motor with our 1/2″ Arbor